Surface Finishing

Many finishing options are available, including sandblasting, aquablasting, polishing, plating, painting, powder coating, pad printing and silk screening, anodizing and machine finishing. We always advise our customers on the best choices for their design.

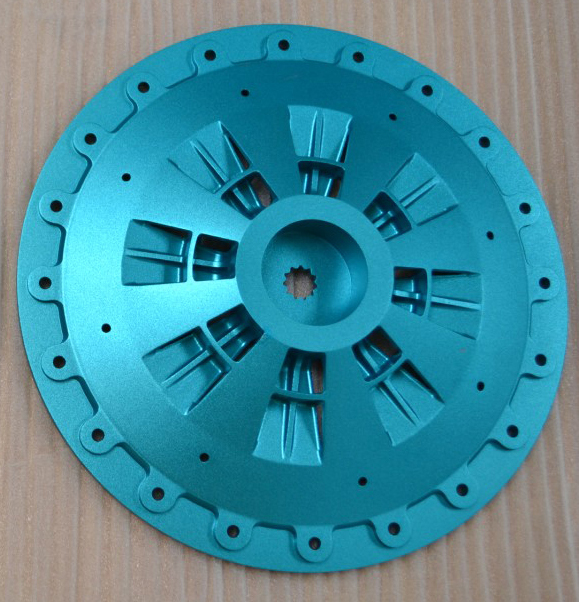

Aluminum Anodizing

The three substrates that can be anodized are aluminum, titanium, and magnesium (steel or stainless steel cannot be anodized). Anodizing will promote the adhesion of paint and many other coatings. We offer primarily type II coatings which means we color the parts.

Type II offers the possibility of an array of colors as for example (but not limited to) the colors shown in the picture. General purposes for anodizing also include:

· wear resistance

· corrosion resistance

· heat dissipation

· non-conductive properties

· improved paint/coating adhesion

· aesthetics

Brush

In order to achieve the brushed finish we utilize 3M® abrasives. We can apply brushed finishes to your custom specifications. Otherwise we usually offer a No.4 or No.6 finish.

Machine Surface Finish

Using high quality solid carbide cutters from the USA and Europe and industry leading CAD/CAM software, we are able to achieve superb surface finishes through high speed machining and cutting strategies.

Painting & Printing

At Mockup Technology we train our craftsmen to perform advanced detailing, painting, and printing of prototypes. With a focus on producing high quality printed and painted prototypes, we also invested in a clean room paint facility,the only one of its kind in China.

Our topcoat facility ensures the absence of silicone contaminants and dust, and also allows us to deal with the extreme humidity in China. Our prototype painting and printing specialists wear full-body suite and full-face active carbon respirators to avoid contaminating the paint in any way.

Color Matching Service

At Mockup Technology we understand very well that the color of your finished product can be as important as its function. We offer extensive color matching services using standardized lighting conditions, and we’ve recently invested in Pantone® plastics opaque selector chips to help clients better visualize the finished look of molded plastic parts.

In the past, molding customers would specify Pantone® colors using a system of colored inks printed on white card stock. These colors are notoriously difficult to match with molded plastic parts because the effect of a three-dimensional part on the color is very dependent upon the thickness and translucency of the molding.