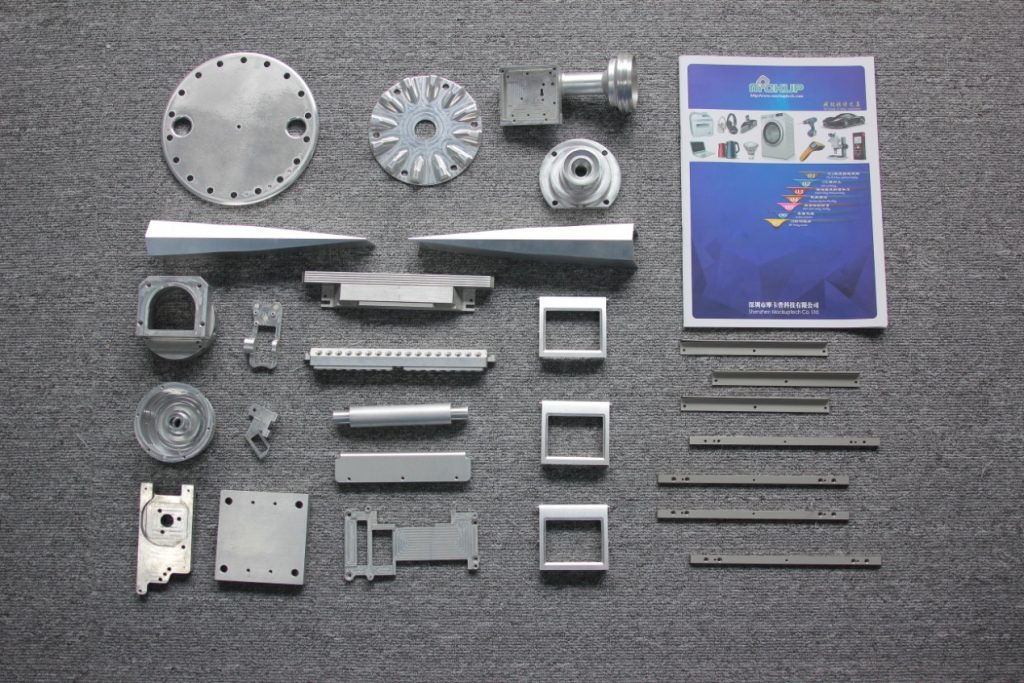

CNC Machining

CNC machining is suitable for plastic and metal parts and can be used to make from one single prototype to up to 500 parts.

A wide variety of materials can be machined, including mild and stainless steel, aluminum, magnesium, zinc, brass and many plastics.

We also offer the production of precision-machined components. Our precision engineering department offers milling, turning, CNC engineering, surface

grinding, wire erosion, EDM spark erosion and more. All of your projects will be discussed carefully and checked before production starts. During and

after production the parts will be 100% inspected and we can provide original certificates for all materials used in the project as well.

● Over 100 sets CNC of 3 to 5-axis and precision CMM

● 16+ years professional experience, CNC 5 axis Top supplier in China

● Custom CNC milling and turning parts, no MOQ requirement

● Low Cost, High Quality with Fast Lead Time

● 24/7 Service, immediate responsiveness, efficient quoting in 1 day

● 100% Customer Satisfaction, exceeding your expectation

3-Axis CNC Milling

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to rapidly cut solid plastic and metal blocks into final parts.

Our CNC milling process produces custom prototypes and end-use production parts in as fast as 1 day.

We use 3-axis milling and 5-axis indexed milling processes to manufacture parts from more than 30 engineering-grade plastics and metals.

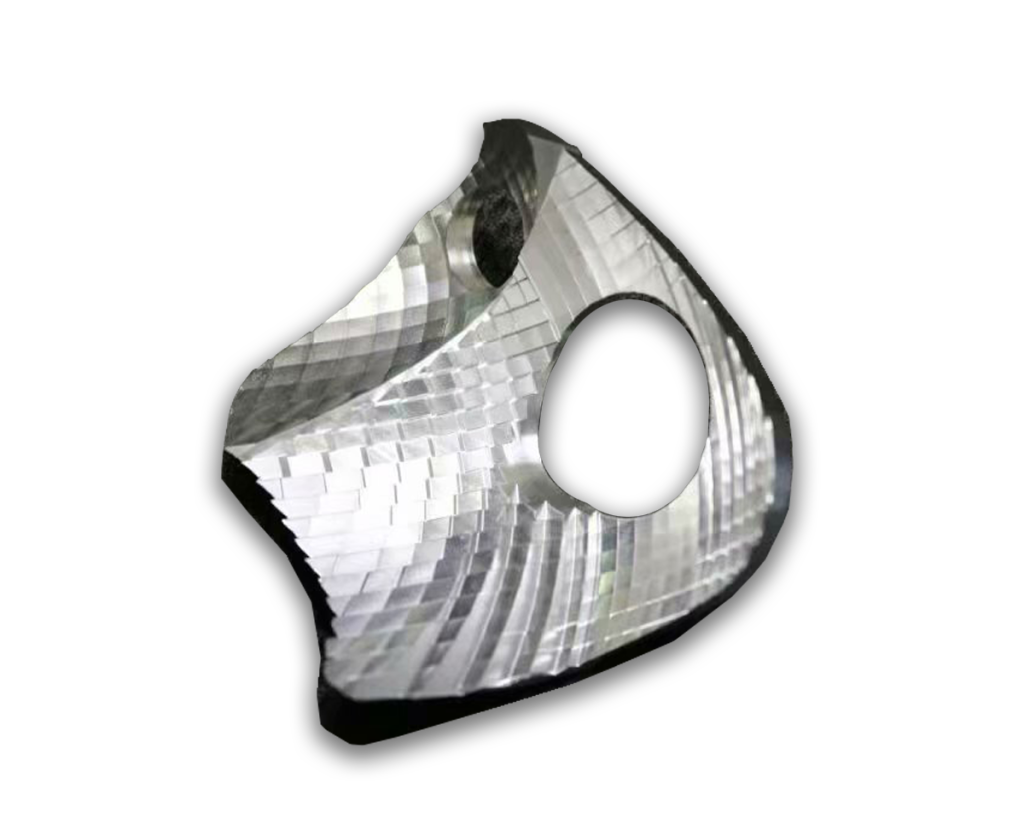

5-Axis CNC Milling

CNC milling is used to apply a machined surface finish on plastic or metal or for creating complex 3D shapes.

We use domestic and imported CNC machining centers with quick-change tooling, programmed using advanced Delcam software.

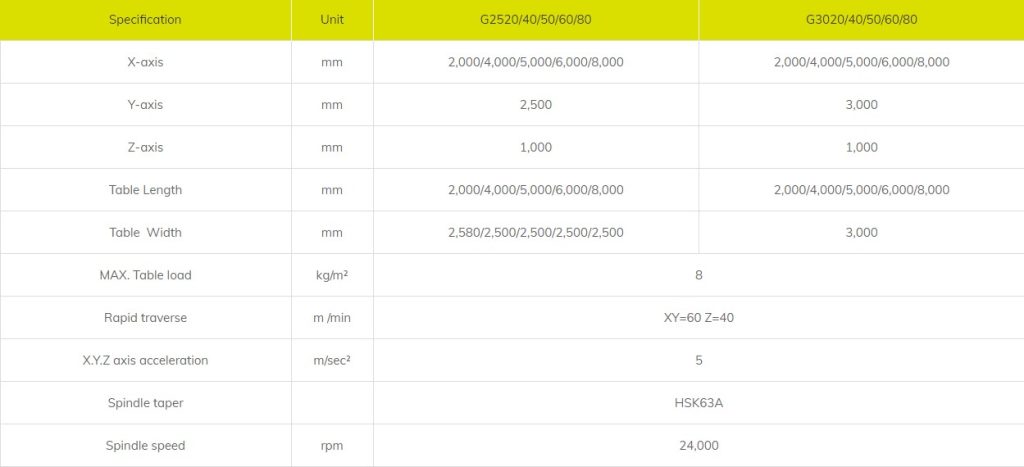

5-axis High Speed Gantry Machining Center from Taiwan

-5-axis simultaneous machining

-U-shaped structure

-X/Y axis driven by linear motor

-Z-axis driven by double ball screws with innovative hollow water cooling technology

CNC Turning

CNC Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

It refers to the automated machining process of shaping material, such as metal or plastic, using a CNC machine.

Our CNC lathes enable high speed and high quality turning of both plastics and metals.

The turning process allows for complex external geometries and internal bores to be generated.

Our turning capacity is available for one-offs through to batch production of your components.

CNC Machining Tolerances

Our general tolerances for CNC machining of metals is DIN-2768-1-fine and for plastics DIN-2768-1-medium. Tolerances are greatly affected by part geometry and type of material, so our project managers will consult with you on every project and will seek to provide the highest degree of precision possible.

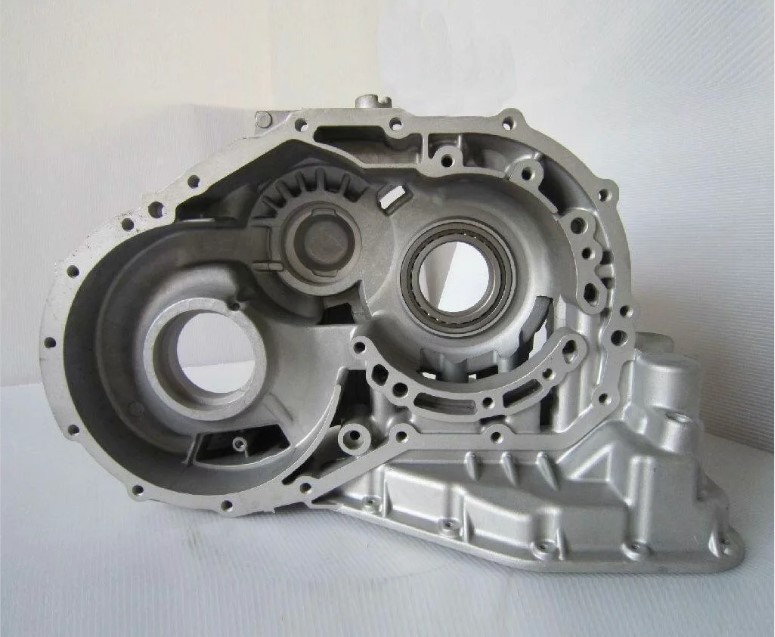

CNC Machining Applications

Aviation equipment, medical equipment, auto parts, bicycle accessories, camera equipment, toy equipment (light sword enclosure), lighting equipment, water meter equipment, mechanical engineering design, kitchen equipment, communications equipment, stage equipment, sports equipment equipment, Computer peripherals, audio equipment, train accessories, security equipment, radiator accessories.

CNC Machining Materials

● Aluminum Alloys: 5052,6061,6063,7075,etc.

● Copper Alloys: 101 Copper,101 Copper, 360 Brass, 936 Bronze etc.

● Plastics: ABS, Acetal, PE, PP,POM, Nylon,PMMA, PEEK, PEI,Teflon,etc.

● Stainless Steels: 303SS, 304SS, 316SS, 420SS,17-4, 1.4305, 1.4301, 1.4401, 1.4435, etc.

● Allloy Steel: 1018, 4130,1045, 4140, 42CrMo4, 40NiCrMo7, 21NiCrMo2, etc.

CNC Machining Finishes

● Anodized with MIL-A-8625F or MIL-DTL-5541F standard etc.

● Sand blasting from # 50-200 etc.

● Powder coating

● Laser carving for logo

● Wire drawing before anodized.

● Screen printing for your cnc turning parts logo or words.

● Electrophoresis.

● Mirror polish

● Heat treatment From HRC32-60 etc.

● Passivation

● Texture for your turning parts