Rapid Prototyping

At Mockup Technology, we specialize in the production of high quality, low cost rapid prototypes.

With a range of technologies at our disposal, we are the perfect one stop shop for all your prototyping needs. Then, when you’re ready we also provide low-volume manufacturing up to hundreds of thousands of parts.

Our rapid prototyping services include CNC machining, 3D printing, RIM, silicone mold and

vacuum casting. Many of our customers produce prototypes for engineering and sales

models, as they are a great way to test form, fit and function. Learn more about prototyping

or send your CAD file to our international team of experts to get a free quote.

Benefits of Prototypes

● Show your customers and investors a model of your product

● Demonstrate the appearance, dimensions and features of your product

● Test your design for its suitability

● Save time and money by identifying and reducing design flaws

● Have the chance to improve your product even more

● Reduce your work load when the time comes to manufacture

Prototyping Services

When you talk to our team about your project they will give you advice on the best manufacturing process to use when making your product.

The main prototyping services we use include:

CNC Machining Prototypes

Using our imported 3, 4 and 5-axis CNC machining centers, our skilled machinists can make CNC

machined prototypes using a wide range of plastics and metals including aluminum, steel, brass, copper, and titanium.

You can also use materials like wood, foam, and fiberglass. Many customers turn to CNC machining to have their prototypes produced out of more durable materials for functional testing.

It’s especially useful for prototyping functional parts in metal or clear PMMA, providing high repeatability and advanced mechanical properties. Our team can help you decide if a CNC machined prototype is right for your project.

3D Printing Rapid Prototypes

SLA & SLS rapid prototypes are ideal for rapid, one-off prototypes. 3D printing process we offer:

-SLA prototyping is a process whereby UV light cures a liquid photopolymer into a solid plastic prototype, layer by layer.

-SLS (selective laser sintering) uses a high-powered laser to fuse powderized nylon, one layer at a time to form a 3D solid.

-Metal 3D printing, also known as direct metal laser sintering (DMLS) and direct metal laser melting (DMLM), is an additive layer technology uses a high-

powered laser to melt and fuse successive layers of powdered metal into three-dimensional solid parts.

-CJP (ColorJet Printing) is often a lower cost option, and is perfect for creating full-color concept models, architectural models, and demonstration models.

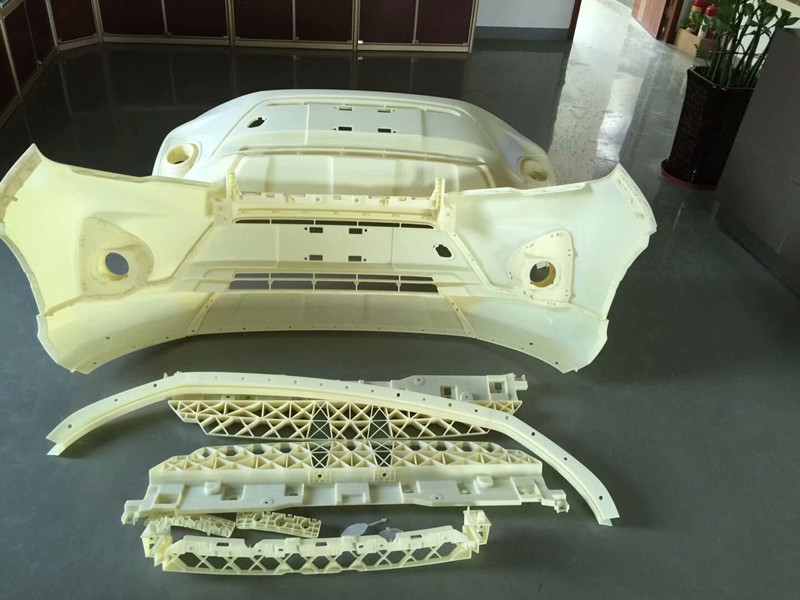

RIM Rapid Injection Prototypes

Reaction Injection Molding (RIM) is the process by which molded polyurethane (PU) parts are made.

In the process, two liquid components are mixed and injected into the mold where they chemically react and cure, which forms the polyurethane polymer parts.

It’s an excellent choice for larger plastic parts produced in short run or low volume production quantities.

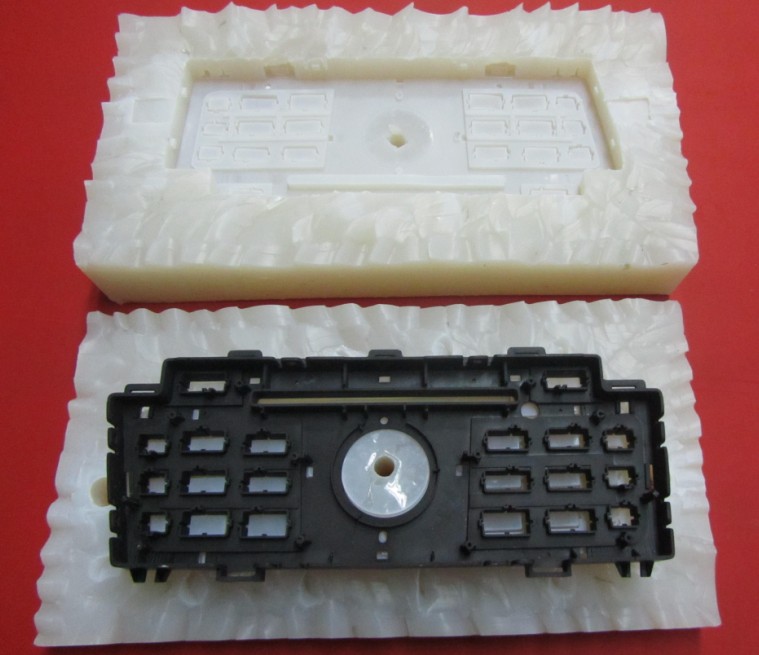

Polyurethane Vacuum Castings

Polyurethane vacuum casting involves a multi-step process.

First a master mold is made of a durable material. Master molds can be customer-supplied

or made using traditional prototyping methods including CNC machining, 3D metal printing,

stereolithography (SLA) or selective laser sintering (SLS).

The master mold is placed inside of a casting box, which is then filled with liquid silicone rubber.

Once the silicone is cured, it is split open and the master removed. There is now an empty cavity conforming to a reverse image of the master. This cavity is then filled with the casting polyurethane (PU) of your choice. A vacuum is applied to the silicone mold, which effectively pulls the PU into any voids inside the mold.

Silicone molds are usually durable enough to make up to 20 or more copies of the original with excellent fidelity.