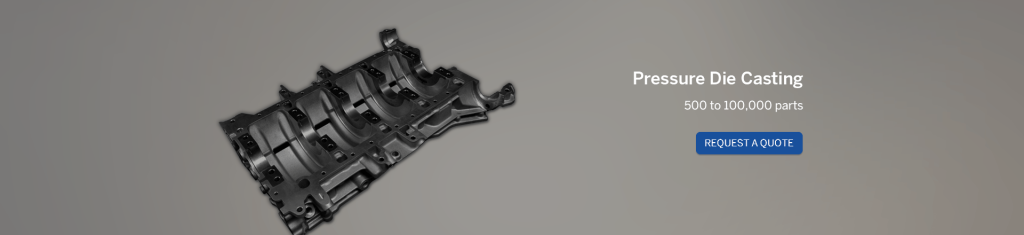

Pressure Die Casting

Making pressure die-cast parts requires expert advice and close on-site monitoring. From project planning to tool making to die casting of parts –our pressure die casting experts will support you throughout the entire project. In China, we are one of the only providers of this level of expertise, service, and quality and our prices are below any quotation from the US, Europe, or Canada.

Pressure die casting is ideal for making multiple copies up to hundreds of thousands of pieces with high surface quality finish. Tooling can also be made to apply a textured surface to your finished parts.

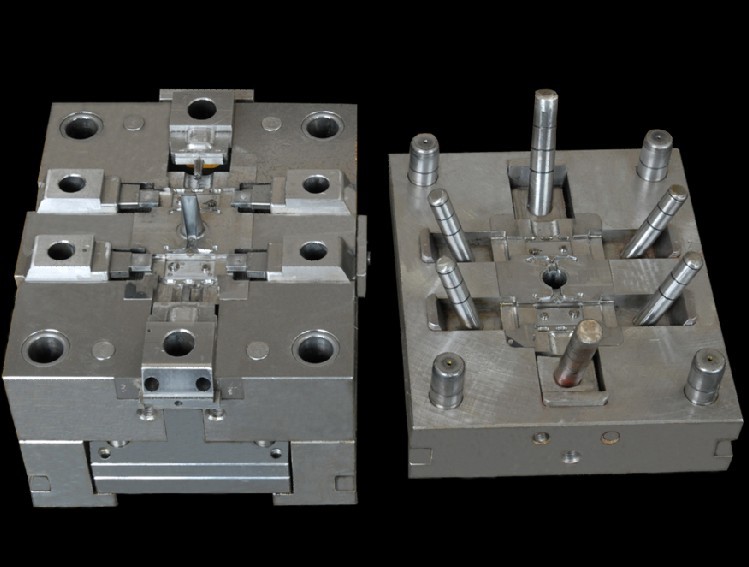

Pressure Die Casting Tool Making

We make tools to pressure die cast various metal parts and components used in automotive, medical and general industrial applications.

For most production we utilize H13 steel with a Rockwell hardness of 42-48. Upon request our customer may also choose other metals for mold tools.

Cast Metals

Your choice of materials will depend on cost, weight and engineering application. Consult our experts for technical advice..

Aluminum Die Casting:

Ideal for strong, complex yet lightweight geometries. Alloys available are ADC12,A380,ADC10 and A413.

Zinc Die Casting:

Mostly used for very ductile parts that may require plating. Casting is fairly easy. Alloys available are Zn 3#,Zn 5#.

Magnesium Die Casting:

For lightweight parts that require a good strength-to-weight ratio. Alloy is AZ91D.

Surface Finishing

Many finishing options are available, including sandblasting, aquablasting, polishing, plating, painting, powder coating, pad printing and silk screening, anodizing and machine finishing. We always advise our customers on the best choices for their design.